Research & Development

Paladin's R&D facility is located at our manufacturing site in Khalapur, Maharashtra, India. Our experienced team of researchers focus mainly on development of innovative high performance products based on renewable biomass, while making sure that the products have commercial competence without any compromise in performance. We are highly motivated by our cause to appropriately utilize our diverse supply of renewable natural resources for the development and replacement of traditional petroleum based raw materials. At Paladin, we try to strike a harmonious balance between industrial development and ecological wellbeing.

Our R&D team has a plethora of experience in the development of resins and paints. Additionally, with our Directors possessing a technical background, we have been committed to scientific research based development of products since 1948. With a well-structured administration that seamlessly incorporates technical professionals, we are very well equipped to understand and fulfil our customer's needs and the changing market requirements.

Green Technology

Oxford dictionary defines Green Technology as a type of technology whose use is intended to mitigate or reverse the effects of human activity on the environment. We at Paladin, strongly believe that technology can be developed without relying on non-renewable sources. Our products are based on scientific and technological manipulations of renewable biomaterials for their high performance applications in marine and protective coatings market. The main source of our renewable raw materials comes from Cashew Nut Shell Liquid, which is a by-product of the Cashew Industry. Cardanol, extracted from the internal soft honeycomb structure of the cashew nut, has a versatile chemical structure that can be modified for a variety of applications, making it a suitable substitute for petroleum derived compounds. Along with protecting the environment, utilizing cardanol in our technology is beneficial to our local communities. Sourcing our cardanol from the Western Ghats of India, supports a large community of rural population for their livelihood and development.

Cashew Nut Shell Liquid

Cashew nut shell liquid (CNSL) or cashew shell oil is a natural compound with a yellowish sheen, extracted from honeycomb structure of the cashew nut shell. It is obtained from a by-product of processing cashews, where the shell is simply discarded as a waste. But one man’s trash is another man’s treasure. Chemically, CNSL is a treasure with a mixture of compounds - anacardic acid, cardol and methyl cardol. Cardanol, obtained from decarboxylation of anacardic acid, is a natural phenol with a side chain that has been found to have interesting structural features, allowing for a wide range of chemical modifications.

Cashew Nut Shell Liquid

Cashew nut shell liquid (CNSL) or cashew shell oil is a natural compound with a yellowish sheen, extracted from honeycomb structure of the cashew nut shell. It is obtained from a by-product of processing cashews, where the shell is simply discarded as a waste. But one man’s trash is another man’s treasure. Chemically, CNSL is a treasure with a mixture of compounds - anacardic acid, cardol and methyl cardol. Cardanol, obtained from decarboxylation of anacardic acid, is a natural phenol with a side chain that has been found to have interesting structural features, allowing for a wide range of chemical modifications.

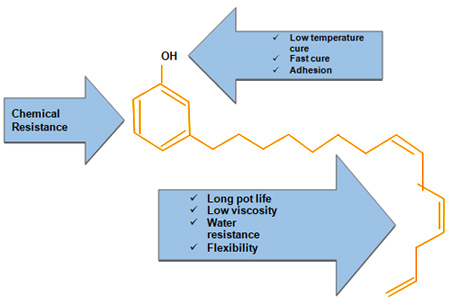

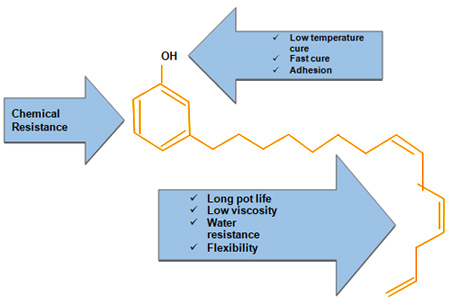

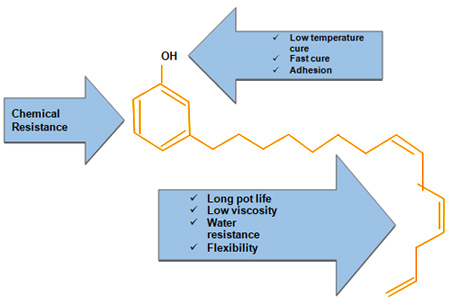

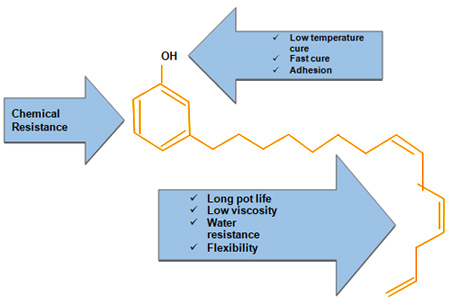

Cardanol’s chemically versatile structure contains an aromatic ring, a phenolic hydroxyl group and double bonds in C15H27 alkyl chain. Our strength in scientific research and technical understanding has enabled us to create a wide spectrum of bio based products from Cardanol.

It is the core material for development of our one pack epoxy resin, phenalkamine curing agents, diluents, modifiers and polyols. The presence of aromatic ring provides excellent chemical, thermal and moisture resistance. The long aliphatic side chain imparts good flexibility, low viscosity and extended pot life. Furthermore, the hydroxyl group offers strong adhesion and reactivity that allows for the unique low temperature curing performance of our phenalkamines.

Paladin's P- series are cardanol based diluents that are intended to replace petroleum based materials and move a step away from toxic and hazardous chemicals. In the future, we plan to continue and expand the use of cardanol in diluents, modifiers and intermediates.

Cardanol based One Pack Epoxy Resins

Epoxy resins are a vast class of prepolymers and polymers containing epoxide groups, also often referred to as glycidyl or oxirane groups. Two pack epoxy systems are ubiquitous in various industries and find their applications in adhesives, coatings and composites, to name a few. But, the current trend is moving more towards replacing traditional two-pack epoxy systems with a one-pack system.

There are several performance improvements and commercial advantages that result from this replacement of two-pack epoxy system with a single pack:

- Elimination of multi-component dispensing and metering equipment, along with associated spare parts

- Reduction of labor needed to maintain meter/mix equipment and components, or to manually weight and mix the product components

- Reduction of labor required to monitor, maintain and clean pumps, vats, scales and other associated manufacturing equipment

- Improved raw-material procurement and logistics by replacing two containers associated with two-pack products with one container for one-pack systems

- Elimination of pot life considerations and line downtime resulting from product advancement exceeding process tolerances

- Elimination of mix-ratio tolerance concerns, with the ever-present risk of using an epoxy system outside its mix-ratio range

- Improved final product quality as a result of more consistent performance in terms of adhesion & flexibility

- Improved worker safety and reduced hazardous-communication requirements with one-pack epoxies resulting from the elimination of volatile and corrosive curing-agent components

- One pack epoxy coatings are surface tolerant and hence user friendly, as they do not need intensive surface preparation as required by 2K epoxy systems

Paladin offers one-pack cardanol modified epoxy resin containing epoxy ether linkages. This system gains its ultimate performance when ambiently cured by an air drying mechanism. Its superior anti-corrosive properties ensure the protection of metallic assets from their natural degradation.

Paladin provides PEPOX series of one-pack epoxy resin systems in order to meet customer specific end use applications.